Above Ground Storage Tanks

Storage Tank Scab Repairs

Problem

Corrosion patching on pipework or external body of tanks. Both large and small scale areas affected.

Solution

Viscotaq visco elastic coating can be cold applied to almost any surface with minimal preparation which effectively bandages any corrosion damaged and pitted areas, protecting them from further damage.

Storage Tank Internal Roof Protection

Problem

- Corrosion of internal surfaces and support structures of storage tank roofs above the product layer from oils that contain sulphur emitting corrosive vapors.

- Unsafe operating conditions and environmental problems caused by aggressive pitting and crevice corrosion that create holes in the tank tops.

- Internal tank coatings are ineffective in preventing dangerous pitting and crevice corrosion, especially in the spaces between the roof and support structures.

- Stoppage of tank operations and necessitating periodic roof replacements impact petrochemical facilities causing capital losses and increased intangible costs.

Solution

The Zerust® ReCAST-R solution is designed to protect the interior surface of AST roofs. It consists of dispensers that deliver the proprietary inhibitor formulations into the vapor space between the surface of the product and tank roof. The Zerust inhibitor forms a protective layer that prevents corrosion in highly-aggressive environments (H2S, SO2, etc). Zerust ReCAST-R solution can be implemented to extend the service life of a single tank roof to 25 years and beyond. Each system is tailored to the client’s requirements, depending on specific environmental conditions, product stored, tank diameter, and can be applied on both new and existing roofs.

Storage Tank Chime Protection (Dry/Flood)

Problem

- Soil Side Bottom (SSB) corrosion of a tank that is in or out of service and has a concrete, bitumen, compacted sand or soil foundation.

- The opportunity costs when storage tanks are out of operation can be crippling.

- Tank operators have to suspend operations in order to complete patchwork repairs, or replace the entire bottoms.

- Storage tank leaks caused by bottom plate corrosion are hazardous to the environment.

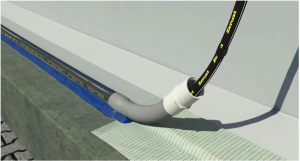

Chime areas on storage tanks are some of the most exposed and critical areas to consider when protecting the tank bottom. This is often the area that water or vapours creep underneath the tank, thus exposing the difficult to reach annual plates to corrosion inducing vapours. Many conventional coatings and systems simply cannot penetrate into these areas so they are left unprotected.

Solution

Chime Ring Dry solution is recommended for storage tanks with concrete or bitumen foundations where our Chime Ring Flood solution is recommended for those with sand, soil or bitsand foundations. Vapor Corrosion Inhibitors (VCIs) are introduced through a dry sleeve system while the tank is in service. Perforated PVC pipe is installed around the entire annular chime area. The VCI dry sleeves are installed into the PVC chime ring and the system is sealed with ViscoTaq to create an enclosure to maintain the VCIs. The VCIs migrate and absorb onto the metal surface. The diffusion of VCIs provides corrosion protection in the critical 3 to 4 meters from the annular chime ring.

Storage Tank Soil Side Bottom Corrosion

Problem

- Soil Side Bottom (SSB) corrosion of a tank that is in or out of service and has a concrete, bitumen, compacted sand or soil foundation.

- The opportunity costs when storage tanks are out of operation can be crippling.

- Tank operators have to suspend operations in order to complete patchwork repairs, or replace the entire bottoms.

- Storage tank leaks caused by bottom plate corrosion are hazardous to the environment.

Solution

Vapor Corrosion Inhibitors (VCIs) Are A Cost-Effective Way to Control Corrosion. Rig Techs solutions provide a cost-effective means to mitigate underside corrosion of aboveground storage tanks while the tanks are in or out of service. Whether tank single or double bottoms rest on compacted sand, concrete, soil or bitumen, Rig Tech has a solution to extend the serviceable life of these assets.